Water is often called the lifeblood of industry, not just for consumption but as a crucial component in manufacturing, cooling, processing, and cleaning operations. However, the presence of hard water can pose significant challenges, from scaling and clogging of equipment to the inefficiency of soap and detergents. This is where industrial water softeners come into play, vital systems designed to mitigate the effects of hard water and improve operational efficiency. In this article, we'll dive deep into the technology behind industrial water softeners, explaining how they work, the benefits they offer, and the considerations industries should take into account when implementing these systems.

What is Hard Water?

Hard water contains high levels of dissolved minerals, primarily calcium and magnesium. While not harmful to human health, these minerals can cause lime scale buildup in pipes, boilers, and other machinery, which can lead to decreased efficiency and increased maintenance costs.

How Do Industrial Water Softeners Work?

Ion Exchange Process

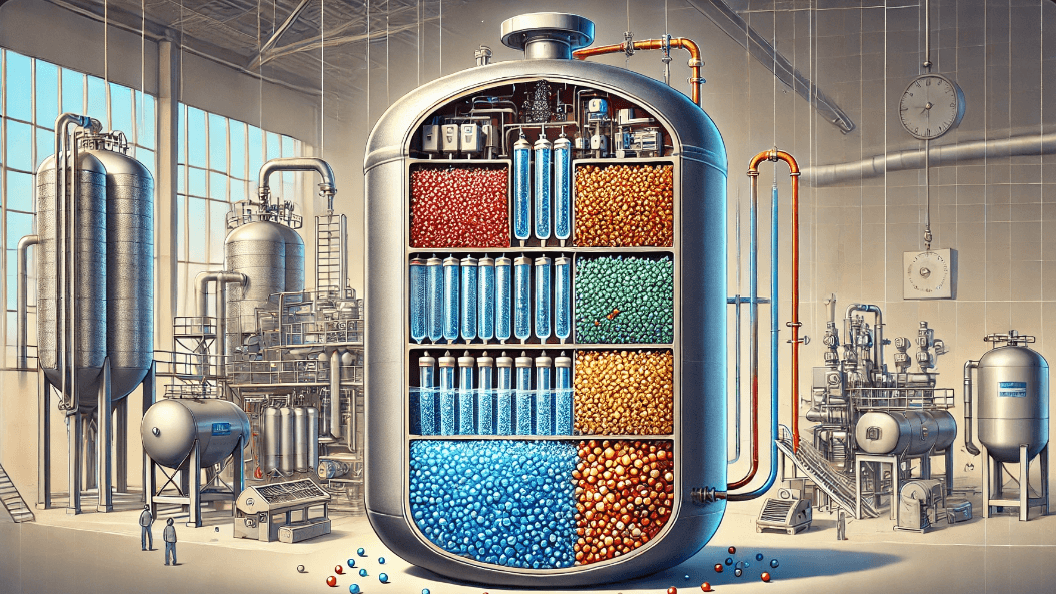

The most common technology used in industrial water softeners is the ion exchange process. This involves exchanging the calcium and magnesium ions in the water with sodium or potassium ions. The core component of this system is a mineral tank filled with resin beads coated with sodium or potassium ions. As hard water passes through the tank, the resin beads attract and hold onto the calcium and magnesium ions, releasing sodium or potassium ions in return.

The Regeneration Cycle

After a certain period, the resin beads become saturated with calcium and magnesium ions and must be regenerated to continue softening water effectively. This process involves flushing the resin tank with a high concentration of salt solution, which replenishes the resin beads with sodium or potassium ions and flushes out the calcium and magnesium ions.

Benefits of Using Industrial Water Softeners

- Extended Equipment Lifespan: By preventing scale buildup, water softeners extend the life of industrial equipment, such as boilers, heat exchangers, and cooling towers.

- Reduced Energy Costs: Equipment runs more efficiently without the insulating effect of scale, thereby consuming less energy.

- Lower Maintenance Costs: The reduction in mineral buildup results in fewer repairs and maintenance requirements.

- Improved Process Efficiency: Soft water improves the effectiveness of soaps and detergents, reducing the necessary quantities and enhancing cleaning processes.

Considerations When Choosing an Industrial Water Softener

Size and Capacity

Choosing the right size and capacity for an industrial water softener is critical. It should be based on the water usage, the hardness of the water, and the peak flow rate required by the facility.

Type of Resin

The choice of resin can affect the efficiency and longevity of a water softener. Fine mesh resin is typically more effective for high iron content, while standard resin suffices for general water softening.

Control Systems

Modern industrial water softeners come equipped with advanced control systems that automate much of the regeneration process, reducing manual intervention and ensuring consistent water quality.

Cost

While the initial investment in an industrial water softener may be significant, the long-term savings in maintenance, energy, and operational efficiency often justify the cost.

Conclusion

Understanding the technology behind industrial water softeners is essential for industries looking to enhance their operational efficiency and protect their equipment. By selecting the appropriate system and ensuring regular maintenance, industries can significantly benefit from the softening of their water supply. In today's environmentally conscious world, optimizing water usage not only saves costs but also contributes to sustainable industrial practices.

This deep dive into the inner workings of industrial water softeners provides a clear picture of their importance and functionality. By investing in the right water treatment solutions, industries can ensure smoother operations and a healthier bottom line.